Get Free Consultation!

We are ready to answer right now! Sign up for a free consultation.

I consent to the processing of personal data and agree with the user agreement and privacy policy

Description

Baode DOC oil cooler are used to exchange heat between oil & collant. They are high performance components and provide a high level of efficiency combined with compact dimensions and low weight. Their efficiency reduces the amount of cooling water required for heat transfer which results in low operating costs.

Features

Plates and connections are manufactured from stainless steel to AISI 316, 1.4401, vacuum–brazed with copper / stainless. The special molding of the plates produces the turbulent flow necessary for effective heat transfer and provides the plate heat exchanger with a high level of mechanical strength. Nickel & Stainless brazed option available

Operating Details

Medium:

• Water glycol (coolants)

• HFC operating fluids

• Water

• Oil

Contamination:

The quantity of particles in suspension should be less than 10 mg/l.

Particle size < 0.6 mm (spherical).

Thread–like particles cause a rapid rise in pressure drops.

Temperature Range:

• 50° to 437°F (10° to 225°C)

(freezing point and boiling point must be taken into consideration!)

Pressure:

• Max Design pressure. 30bar / 45bar

• Test pressure: 45bar/60bar

Corrosion:

The following limits refer to a pH value of 7

• free chlorine, CL2 < 0.5 ppm

• chloride ions CL

< 700 ppm at 20 °C

< 200 ppm at 50 °C

Other Limits:

• ph 7 – 10

• sulphate SO4 2– <100 ppm

• [H CO3 –] / [SO4 2– ] >1

• ammonia, NH3 <10 ppm

• free CO < 10 ppm

The following ions are not corrosive under normal condi- tions: phosphate, nitrate, nitrite, iron, manganese, sodium and potassium

Applictions:

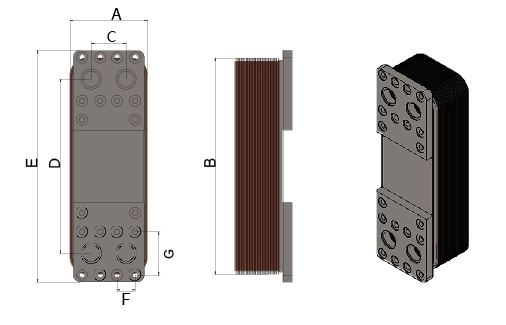

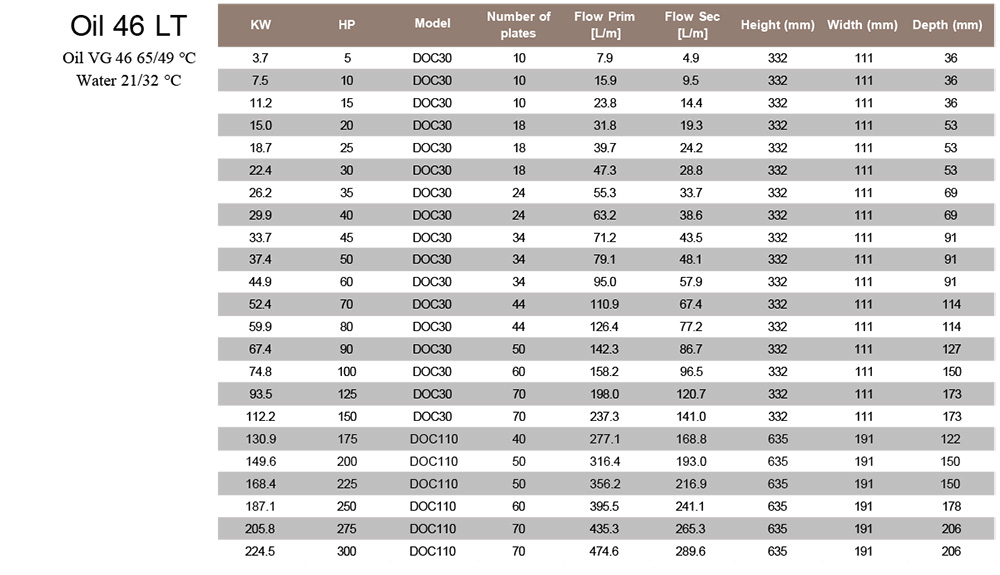

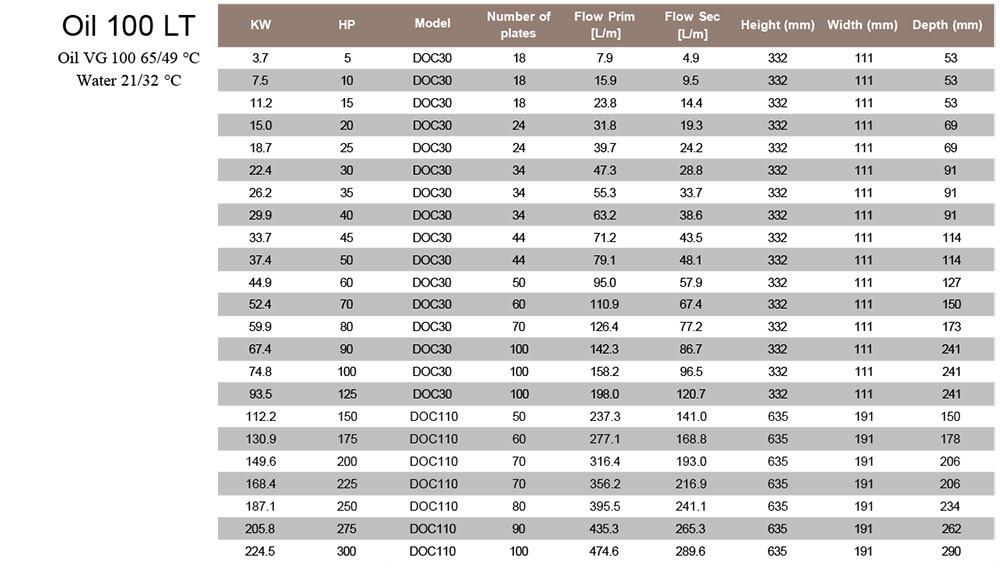

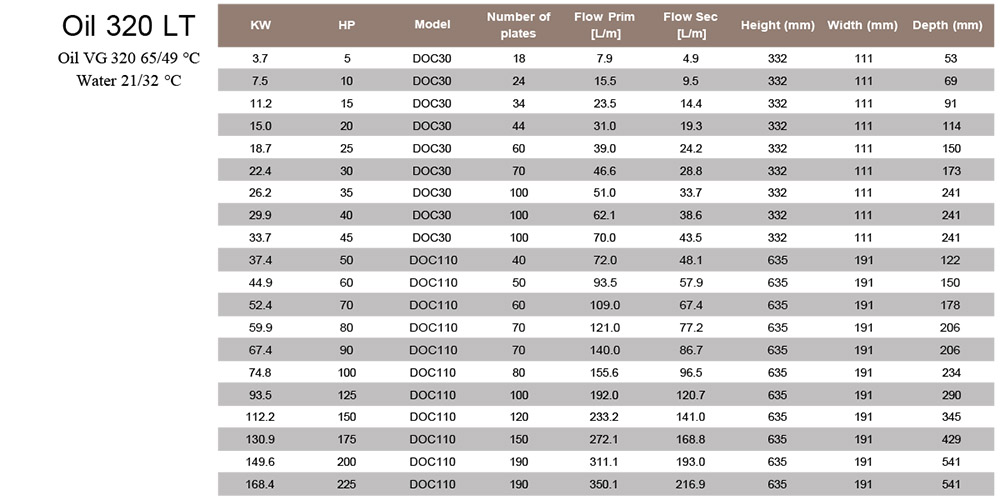

Model | A | B | C | D | E | F | G |

DOC30 | 111 | 310 | 50 | 250 | 332 | 28 | 62 |

DOC60 | 111 | 525 | 50 | 466 | 548 | 28 | 62 |

DOC110 | 191 | 616 | 92 | 519 | 635 | 40 | 90 |

The Baode DOC Oil Cooler is a high-performance heat exchanger designed to efficiently transfer heat between oil and coolant. These compact units provide exceptional thermal performance, helping reduce operating costs by minimizing the amount of cooling water required. Their lightweight design and compact dimensions make them ideal for industries where space constraints and efficiency are paramount.

Manufactured from high-quality stainless steel AISI 316 (1.4401) and vacuum-brazed with copper or nickel, these oil coolers offer excellent mechanical strength and resistance to corrosion. With options for nickel and stainless brazing, the Baode DOC Oil Coolers can be adapted to meet the demanding requirements of various applications, including industrial cooling, automotive systems, and hydraulic circuits.

The oil cooler functions by transferring heat from hot oil to a cooling medium such as water glycol, water, or HFC operating fluids. As the hot oil flows through one set of channels and the coolant flows through adjacent channels in the brazed plate heat exchanger (BPHE), heat is transferred between the two fluids without mixing.

The corrugated plate design creates turbulence within the fluid streams, enhancing heat transfer efficiency. This turbulence improves mixing and prevents stagnant zones, ensuring consistent thermal performance. Thanks to the compact size and lightweight construction, these coolers are easy to install and integrate into various industrial and automotive systems.

High-Efficiency Thermal Transfer

The turbulent flow paths within the exchanger’s plates ensure optimal heat transfer, reducing the amount of coolant needed. This efficiency helps lower operating costs by minimizing energy consumption and the demand for cooling water.

Compact and Lightweight Design

The oil cooler’s small footprint makes it suitable for installations with space constraints. Despite its compact size, the oil cooler offers high mechanical strength, allowing it to perform reliably in demanding environments.

Durable Stainless-Steel Construction

The plates and connections are made from AISI 316 stainless steel, which ensures high corrosion resistance and durability. This makes the oil cooler ideal for use in harsh environments, such as marine or industrial applications.

Nickel and Stainless Brazing Options

For applications that require greater corrosion resistance, nickel or stainless brazing options are available, extending the life of the exchanger even in aggressive fluid environments.

Vacuum-Brazed Joints for Leak-Free Operation

The brazing process creates leak-proof joints between the plates, ensuring reliable performance under high pressure and reducing the risk of cross-contamination between fluids.

The Baode DOC Oil Cooler is designed to operate across a wide range of temperatures and pressures, ensuring versatility and reliability in various industrial and commercial applications.

The oil cooler is compatible with several cooling and lubricating fluids, including:

These media ensure optimal cooling for hydraulic circuits, automotive systems, and industrial processes.

The heat exchanger can withstand temperatures ranging from 50°F to 437°F (10°C to 225°C). However, the freezing and boiling points of the fluids used must be carefully considered to prevent damage to the unit.

These pressure ratings ensure the oil cooler can handle high-pressure systems, such as automotive engines and industrial equipment.

For optimal performance and longevity, it is important to maintain fluid purity and follow the recommended contamination limits:

To prevent corrosion and ensure the longevity of the oil cooler, the following chemical limits should be observed:

The unit is resistant to common ions like phosphate, nitrate, nitrite, iron, manganese, sodium, and potassium under normal conditions, ensuring safe and reliable operation in various environments. It is recommended to maintain a pH level between 7 and 10 to prevent chemical degradation of the materials.

The Baode DOC Oil Cooler is suitable for use in a wide range of industrial and commercial applications, including:

Higher Efficiency and Lower Operating Costs

The Baode DOC oil coolers require less coolant to achieve the desired heat transfer, reducing energy consumption and operating costs over time.

Space-Saving Design

Thanks to their compact size and low weight, Baode oil coolers are easier to install than traditional shell-and-tube heat exchangers. This makes them ideal for applications where space is limited.

Reliable Performance Under High Pressure and Temperature

With pressure ratings up to 45 bar and temperature resistance up to 437°F (225°C), Baode DOC oil coolers can handle demanding conditions without compromising performance.

Corrosion Resistance for Longevity

Constructed from AISI 316 stainless steel and available with nickel or stainless brazing options, these oil coolers are built to withstand corrosion, ensuring a long service life.

Easy Integration and Minimal Maintenance

The compact design and leak-proof construction ensure minimal maintenance requirements, reducing downtime and increasing system reliability.

The Baode DOC Oil Cooler is a highly efficient, compact, and durable solution for heat transfer between oil and coolant in various applications. Whether used in automotive engines, hydraulic systems, marine vessels, or industrial equipment, these oil coolers deliver exceptional performance with reduced operating costs.

With features like nickel and stainless brazing options, high corrosion resistance, and easy integration, the Baode DOC oil cooler offers unmatched versatility and reliability. If you are looking for a cost-effective, high-performance oil cooling solution, the Baode DOC oil cooler is the ideal choice to meet your operational needs.