Mge Tech BL30 Brazed Plate Heat Exchanger: Compact Performance for Diverse Applications

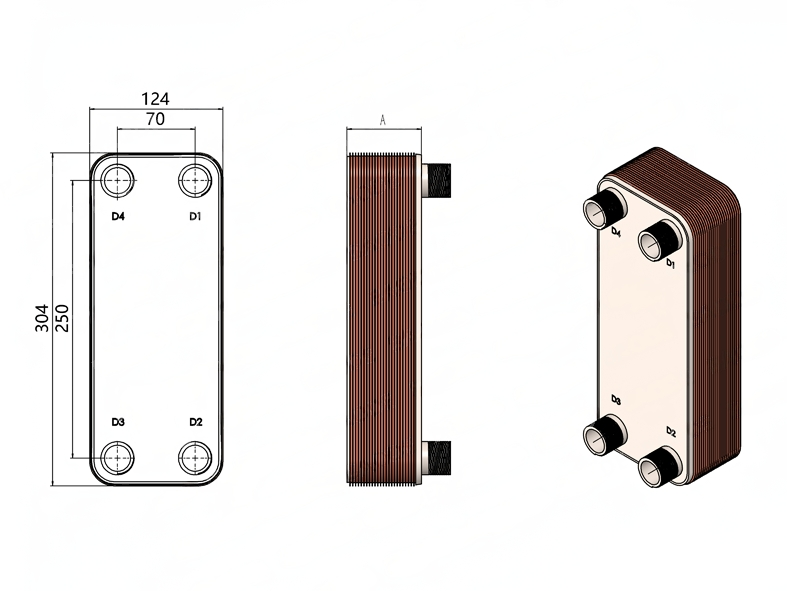

| Model Details | Model | BL30 | ||

| Flow Pattern | parallel |  | ||

| Weight (kgs) | 2.2+0.16N | Approval | UL, CE, BV, DNV, GL, ISO9001, ISO14001 | |

| Max Flow (m3/h) | 12.7 | Max Pressure (bar) | 30 / 45 | |

| Plate Material | SS 304 / SS 316L | Max Temperature ℃ | 200 | |

| Conneciton Material | SS 304 | Min Temperature ℃ | -190 | |

| Brazing Material | Copper / Nickle | Packing | Individual box / Polywood box | |

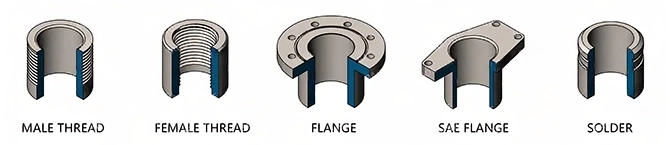

| Connection Type | Thread, Solder, Flange | Mount Bracket(Optional) | Studs, Brazcket, Feet | |

| Max Connection Size | 1.25‘’ | |||

| Freon | R22, R401, R407, R515A | |||

The Mge Tech BL30 brazed plate heat exchanger exemplifies innovative engineering, designed to deliver exceptional thermal efficiency in a compact format. Ideal for various industrial applications, this model stands out for its reliability, robust construction, and versatility.

Product Overview

The BL30 features a parallel flow pattern, optimizing heat transfer while minimizing the required installation space. This model is built to meet the demands of a wide range of applications, making it a top choice for industries requiring efficient heat exchange solutions. Below are the detailed specifications and features of the BL30:

Key Features

Efficient Parallel Flow Design: The parallel flow pattern enhances thermal efficiency, allowing for optimal heat transfer across various applications, which contributes to reduced energy costs.

Lightweight and Compact: Weighing only 2.2 kg, the BL30 is easy to install and fits seamlessly into systems with space constraints.

Durable Construction: Crafted from high-quality stainless steel (SS 304 / SS 316L), the BL30 is designed to withstand harsh conditions, ensuring long-lasting performance.

Wide Temperature Range: With an operating range from -190°C to 200°C, the BL30 is suitable for both heating and cooling applications across various industries.

Flexible Connection Options: The model supports multiple connection types (thread, solder, or flange), providing versatility for different installation needs.

Optional Mounting Solutions: The availability of optional mounting brackets allows for easy and secure installation, enhancing stability and accessibility.

Safety and Quality Assurance: The BL30 meets stringent international safety and quality standards (UL, CE, BV, DNV, GL) and is certified under ISO 9001 and ISO 14001, ensuring reliability for customers.

Thoughtful Packaging: Each unit is carefully packed in an individual box or polywood box, ensuring protection during shipping and storage.

Applications

The Mge Tech BL30 brazed plate heat exchanger is versatile and suitable for numerous applications, including:

HVAC Systems: The BL30 is an integral component in heating, ventilation, and air conditioning systems, facilitating effective climate control in commercial and industrial settings.

Refrigeration: This model excels in refrigeration applications, providing reliable cooling and energy efficiency, making it ideal for food processing and storage.

Food and Beverage Processing: The BL30 effectively manages thermal processes in food production, including pasteurization and cooling, meeting stringent safety and quality regulations.

Chemical Processing: The BL30 is effective in chemical applications, where reliable thermal management is crucial for ensuring process efficiency and safety.

Advantages of Mge Tech BL30

Innovative Design and Engineering: The BL30 is the result of Mge Tech’s commitment to innovative design, ensuring high performance and efficiency in diverse applications.

Quality Assurance: Each unit undergoes rigorous quality control processes, providing peace of mind regarding the reliability and performance of the BL30.

Energy Efficiency: The BL30’s efficient design translates to significant energy savings, helping businesses reduce operational costs while supporting sustainability initiatives.

Comprehensive Customer Support: Mge Tech provides exceptional customer service, including expert advice and tailored solutions to meet specific needs.

Installation and Maintenance

Installation

Installing the Mge Tech BL30 brazed plate heat exchanger is a straightforward process. Here’s a step-by-step guide:

Preparation: Clear the installation area and gather necessary tools. Review the installation manual for specific instructions relevant to your system.

Connection Setup: Select the appropriate connection type (thread, solder, or flange) based on your system requirements. Ensure all connections are secure to avoid leaks.

Mounting: If using optional mounting brackets, secure the BL30 in place to ensure stability and accessibility.

Testing: After installation, conduct a series of tests to confirm that the heat exchanger operates correctly and efficiently.

Maintenance

Regular maintenance is vital to ensure the longevity and efficiency of the BL30. Here are some maintenance tips:

Routine Inspections: Periodically inspect the heat exchanger for signs of wear, corrosion, or leaks. Early detection can prevent more significant issues.

Cleaning Procedures: Depending on application specifics, regular cleaning may be necessary to eliminate contaminants. Follow manufacturer guidelines for effective cleaning.

Performance Monitoring: Continuously monitor flow rates, temperatures, and pressures to ensure the BL30 operates within specified limits.

Professional Maintenance: Schedule regular professional maintenance to keep the heat exchanger in optimal condition and extend its lifespan.

Conclusion

The Mge Tech BL30 brazed plate heat exchanger is a robust and efficient solution for effective thermal management across a wide range of industrial applications. With its advanced design, durable construction, and exceptional performance, the BL30 is an ideal choice for businesses looking to enhance their heat exchange processes.

Whether utilized in HVAC, refrigeration, food processing, or chemical applications, the BL30 delivers reliability and efficiency that businesses can trust. For more information or to discuss your specific requirements, please contact us at info@mge-tech.com or call +86 18360805587. Choose Mge Tech for innovative heat exchanger solutions that propel your business forward.