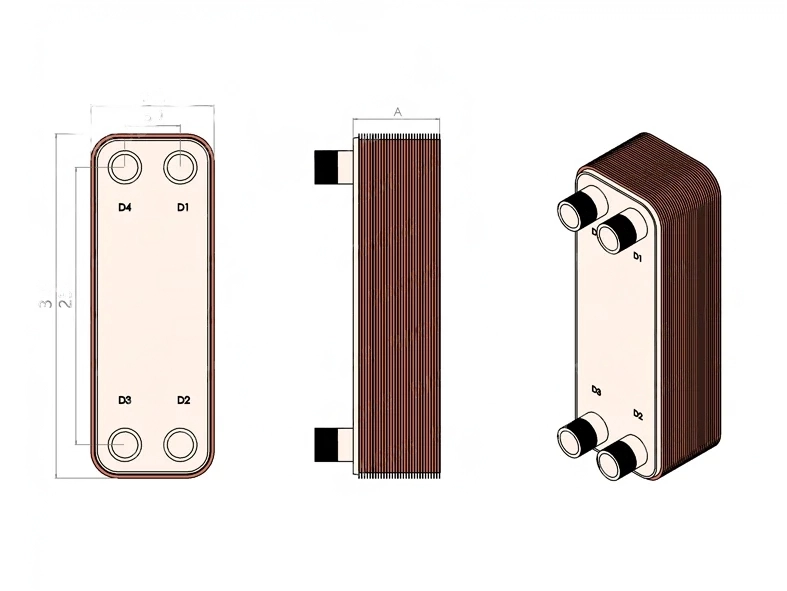

Mge Tech BL26 Brazed Plate Heat Exchanger: Compact, Efficient, and Versatile

| Model Details | Model | BL26 | ||

| Flow Pattern | parallel |  | ||

| Weight (kgs) | 1.3+0.12N | Approval | UL, CE, BV, DNV, GL, ISO9001, ISO14001 | |

| Max Flow (m3/h) | 8.1 | Max Pressure (bar) | 30 / 45 | |

| Plate Material | SS 304 / SS 316L | Max Temperature ℃ | 200 | |

| Conneciton Material | SS 304 | Min Temperature ℃ | -190 | |

| Brazing Material | Copper / Nickle | Packing | Individual box / Polywood box | |

| Connection Type | Thread, Solder, Flange | Mount Bracket(Optional) | Studs, Brazcket, Feet | |

| Max Connection Size | 1‘’ | |||

| Freon | R22, R401, R407, R515A | |||

The Mge Tech BL26 brazed plate heat exchanger is engineered for superior thermal performance in a compact design. This model is ideal for various industrial applications, offering exceptional heat transfer efficiency and reliable operation, making it a preferred choice in the industry.

Product Overview

The BL26 features a parallel flow pattern, enhancing its efficiency in transferring heat. It is designed to meet the rigorous demands of industrial applications, ensuring durability, versatility, and ease of installation. Below are the detailed specifications and features of the BL26:

Key Features

Efficient Parallel Flow Design: The parallel flow pattern optimizes heat transfer efficiency, allowing the BL26 to maintain high performance across various applications.

Lightweight and Compact: At just 1.3 kg, the BL26 is easy to install and transport, making it suitable for applications where space is limited.

Robust Construction: Manufactured from high-quality stainless steel (SS 304 / SS 316L), the BL26 is designed to withstand challenging operating conditions, ensuring durability and longevity.

Wide Temperature Range: Capable of operating between -190°C and 200°C, this heat exchanger is versatile enough to handle both heating and cooling processes.

Flexible Connection Options: The BL26 supports multiple connection types (thread, solder, or flange), enhancing its adaptability for different installation requirements.

Optional Mounting Solutions: With optional mounting brackets available, users can easily secure the BL26 in place for improved stability and ease of access.

Safety and Quality Assurance: The BL26 meets international safety and quality standards (UL, CE, BV, DNV, GL) and is certified under ISO 9001 and ISO 14001, ensuring reliability in performance.

Thoughtful Packaging: Each unit is packaged in an individual box or polywood box, ensuring protection during shipping and storage.

Applications

The Mge Tech BL26 brazed plate heat exchanger is versatile and suitable for a wide range of applications, including:

HVAC Systems: The BL26 plays a vital role in heating, ventilation, and air conditioning systems, effectively managing temperature and humidity in commercial and industrial settings.

Refrigeration: This model is highly effective in refrigeration applications, providing reliable cooling performance essential for food processing and storage facilities.

Food and Beverage Processing: The BL26 is designed to handle thermal processes in food production, including pasteurization and cooling, complying with strict safety and quality regulations.

Chemical Processing: In chemical applications, the BL26 ensures efficient thermal management, essential for maintaining process efficiency and safety.

Advantages of Mge Tech BL26

Innovative Design and Engineering: The BL26 is a result of Mge Tech’s commitment to advanced engineering, ensuring high performance and efficiency across diverse applications.

Quality Assurance: Each unit undergoes rigorous quality checks, providing customers with confidence in the reliability and performance of the BL26.

Energy Efficiency: The efficient design of the BL26 contributes to significant energy savings, helping businesses reduce operational costs while promoting sustainability.

Comprehensive Customer Support: Mge Tech offers exceptional customer service, providing expert advice and tailored solutions to meet specific customer needs.

Installation and Maintenance

Installation

Installing the Mge Tech BL26 brazed plate heat exchanger is straightforward. Here’s a step-by-step guide:

Preparation: Clear the installation area and gather necessary tools. Review the installation manual for specific guidance relevant to your system.

Connection Setup: Choose the appropriate connection type (thread, solder, or flange) based on your specific system requirements. Ensure all connections are secure to prevent leaks.

Mounting: If utilizing optional mounting brackets, securely fasten the BL26 to ensure stability and ease of accessibility.

Testing: After installation, conduct a series of tests to confirm that the heat exchanger is operating efficiently and within specified limits.

Maintenance

Regular maintenance is essential for the longevity and efficiency of the BL26. Here are some maintenance tips:

Routine Inspections: Periodically check the heat exchanger for signs of wear, corrosion, or leaks. Early detection can prevent more significant issues down the line.

Cleaning Procedures: Depending on specific application needs, regular cleaning may be necessary to remove contaminants. Follow manufacturer guidelines for effective cleaning.

Performance Monitoring: Continuously monitor flow rates, temperatures, and pressures to ensure the BL26 operates within specified limits.

Professional Maintenance: Schedule regular professional maintenance to keep the heat exchanger in optimal condition, extending its operational lifespan.

Conclusion

The Mge Tech BL26 brazed plate heat exchanger is an efficient, compact solution for effective thermal management in various industrial applications. With its advanced design, durable construction, and exceptional performance, the BL26 is an ideal choice for businesses seeking to enhance their heat exchange processes.

Whether used in HVAC, refrigeration, food processing, or chemical applications, the BL26 delivers reliability and efficiency that businesses can trust. For more information or to discuss your specific requirements, please contact us at info@mge-tech.com or call +86 18360805587. Choose Mge Tech for innovative heat exchanger solutions that drive your business forward.