Mge Tech BL210 Brazed Plate Heat Exchanger: An In-Depth Analysis

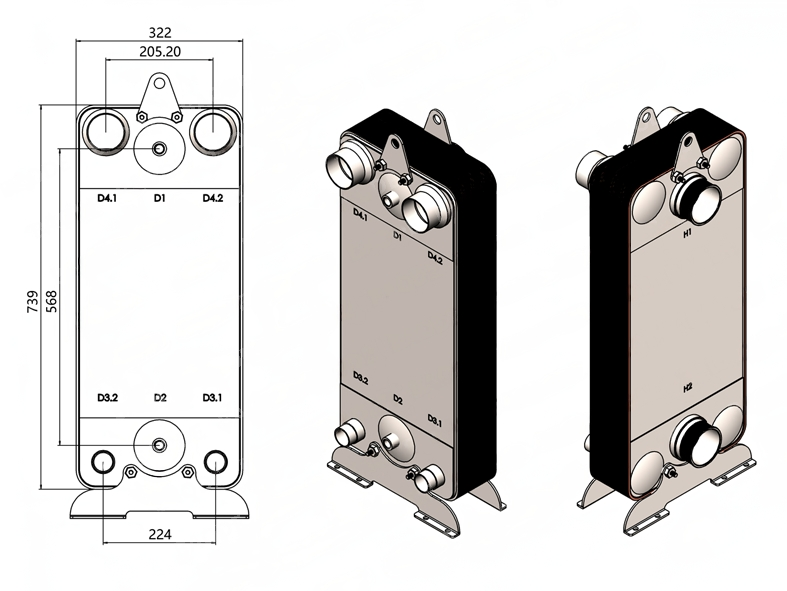

| Model Details | Model | BL210 | ||

| Flow Pattern | Diagonal |  | ||

| Weight (kgs) | 13+0.75N | Approval | UL, CE, BV, DNV, GL, ISO9001, ISO14001 | |

| Max Flow (m3/h) | 100 | Max Pressure (bar) | 30 / 45 | |

| Plate Material | SS 304 / SS 316L | Max Temperature ℃ | 200 | |

| Conneciton Material | SS 304 | Min Temperature ℃ | -190 | |

| Brazing Material | Copper / Nickle | Packing | Individual box / Polywood box | |

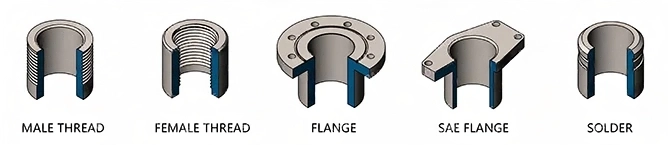

| Connection Type | Thread, Solder, Flange | Mount Bracket(Optional) | Studs, Brazcket, Feet | |

| Max Connection Size | 3‘’ | |||

| Freon | R22, R401, R407, R515A | |||

In industrial settings, efficient heat transfer is crucial for maintaining optimal operational performance. The Mge Tech BL210 brazed plate heat exchanger stands out as a high-performance solution designed to meet diverse thermal management needs across various industries. With its innovative design and robust construction, the BL210 is engineered to provide superior heat transfer efficiency while maintaining a compact footprint.

Product Overview

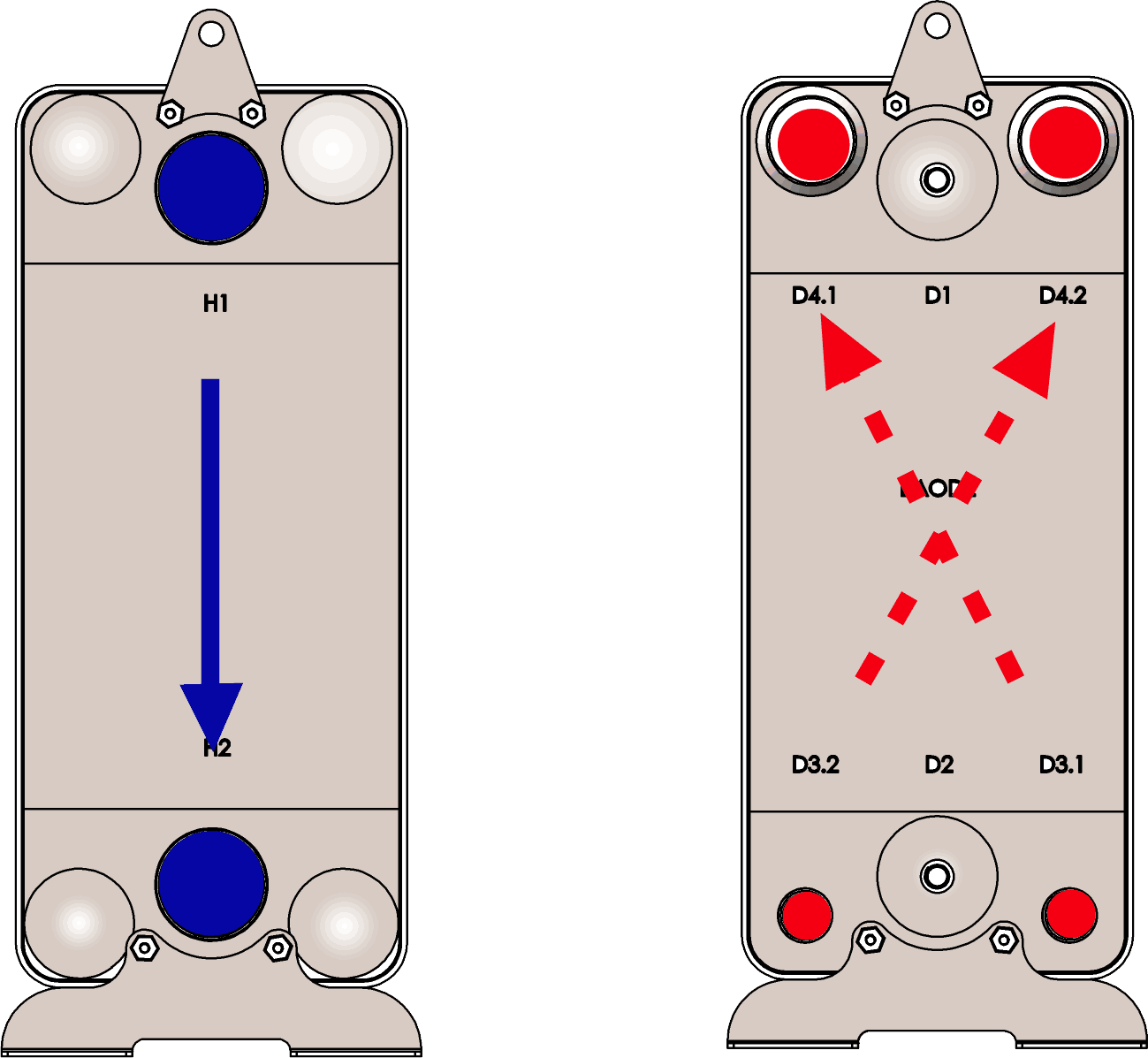

The Mge Tech BL210 brazed plate heat exchanger features a diagonal flow pattern, allowing for enhanced turbulence and improved heat transfer rates. It is specifically designed for applications that demand high reliability and efficiency in fluid handling. Below are the key specifications and features of the BL210 model:

Key Features

Diagonal Flow Pattern: The BL210’s diagonal flow design enhances heat transfer efficiency by promoting turbulence within the fluid channels. This results in superior thermal performance compared to traditional designs.

Compact and Lightweight: Weighing only 13 kg, the BL210 is designed for easy installation and maintenance. Its compact size makes it suitable for applications where space is limited.

High Corrosion Resistance: Made from stainless steel (SS 304 / SS 316L), the BL210 is built to withstand corrosive environments, ensuring longevity and reliability in various applications.

Wide Temperature Range: With a maximum operating temperature of 200°C and a minimum of -190°C, this heat exchanger can accommodate a diverse range of applications, from refrigeration to chemical processing.

Versatile Connection Options: The BL210 supports various connection types, including thread, solder, and flange, allowing for easy integration into existing systems.

Customizable Mounting Solutions: Optional mounting brackets (studs, brackets, or feet) provide flexibility for installation, enhancing usability across different settings.

Compliance with Safety Standards: The BL210 is certified by international safety standards (UL, CE, BV, DNV, GL) and adheres to environmental management standards (ISO 14001), ensuring its reliability and compliance in demanding applications.

Efficient Packaging: Each unit is securely packed in an individual box or polywood box, ensuring protection during transportation and delivery.

Applications

The Mge Tech BL210 brazed plate heat exchanger is highly versatile and can be utilized in a wide array of applications, including:

HVAC Systems: Ideal for heating, ventilation, and air conditioning systems, where efficient heat exchange is crucial for maintaining desired temperatures.

Refrigeration Systems: Perfect for commercial and industrial refrigeration units, providing effective cooling performance while minimizing energy consumption.

Chemical Processing: Designed to handle the rigorous demands of chemical processing applications, where durability and efficiency are paramount.

Oil Cooling Systems: Essential for hydraulic and lubrication systems, the BL210 ensures optimal temperature control, enhancing equipment reliability and lifespan.

Advantages of Mge Tech BL210

Choosing the Mge Tech BL210 brazed plate heat exchanger comes with several advantages:

Expertise and Innovation: Mge Tech is committed to delivering cutting-edge solutions tailored to the needs of diverse industries. Our team of experts continuously invests in research and development to enhance product performance and efficiency.

Quality Assurance: Our heat exchangers undergo stringent quality control measures to ensure they meet the highest international standards. Each product is tested for performance, durability, and safety before it reaches our customers.

Energy Efficiency: The design of the BL210 is optimized for energy conservation, helping clients reduce operational costs while minimizing their environmental impact.

Customer-Centric Approach: We prioritize our clients’ needs, providing personalized solutions and comprehensive support throughout the purchasing process and beyond.

Installation and Maintenance

Installation

The installation of the Mge Tech BL210 is straightforward, thanks to its user-friendly design. Here are some key steps for a successful installation:

Preparation: Ensure that the installation area is clean and free from debris. Verify that the necessary tools and materials are available for the installation.

Connection: Choose the appropriate connection type (thread, solder, or flange) based on your system requirements. Make sure that the connections are secure to prevent any leaks.

Mounting: Use the optional mounting brackets (studs, brackets, or feet) to securely install the BL210 in the desired location.

Testing: After installation, conduct a thorough inspection and testing to ensure that the unit operates correctly and efficiently.

Maintenance

To ensure the longevity and optimal performance of the BL210 brazed plate heat exchanger, regular maintenance is essential. Here are some maintenance tips:

Visual Inspection: Regularly inspect the heat exchanger for any signs of wear, corrosion, or leaks. Address any issues promptly to prevent further damage.

Cleaning: Depending on the application, periodic cleaning may be required to remove any buildup of contaminants that could hinder performance. Follow the manufacturer’s guidelines for cleaning procedures.

Performance Monitoring: Monitor the performance of the heat exchanger regularly, checking flow rates, temperatures, and pressures to ensure it operates within specified limits.

Professional Servicing: Consider scheduling periodic professional servicing to maintain optimal performance and extend the lifespan of the unit.

Conclusion

The Mge Tech BL210 brazed plate heat exchanger is an outstanding choice for industries requiring efficient and reliable heat transfer solutions. With its innovative diagonal flow design, robust construction, and versatile applications, the BL210 meets the diverse needs of modern industrial operations.

Whether you are in HVAC, refrigeration, chemical processing, or oil cooling applications, the BL210 provides superior performance and durability, ensuring that your operational efficiency remains at the highest level. For more information or to discuss your specific requirements, please contact us at info@mge-tech.com or call +86 18360805587. Choose Mge Tech for cutting-edge heat exchanger solutions that drive your success.