Mge Tech BL190 Brazed Plate Heat Exchanger: Efficiency Meets Durability

| Model Details | Model | BL190 | ||

| Flow Pattern | parallel |  | ||

| Weight (kgs) | 12.5+0.72N | Approval | UL, CE, BV, DNV, GL, ISO9001, ISO14001 | |

| Max Flow (m3/h) | 100 | Max Pressure (bar) | 30 / 45 | |

| Plate Material | SS 304 / SS 316L | Max Temperature ℃ | 200 | |

| Conneciton Material | SS 304 | Min Temperature ℃ | -190 | |

| Brazing Material | Copper / Nickle | Packing | Individual box / Polywood box | |

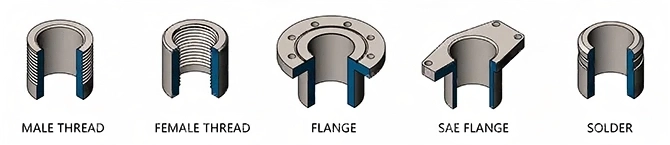

| Connection Type | Thread, Solder, Flange | Mount Bracket(Optional) | Studs, Brazcket, Feet | |

| Max Connection Size | 3‘’ | |||

| Freon | R22, R401, R407, R515A | |||

In the industrial landscape, effective heat transfer is crucial for optimal operational efficiency. The Mge Tech BL190 brazed plate heat exchanger is engineered to provide outstanding thermal performance in a compact and robust design. Suitable for a wide range of applications, this heat exchanger is a testament to Mge Tech’s commitment to quality and innovation.

Product Overview

The BL190 model features a parallel flow pattern, designed specifically to enhance heat transfer efficiency. With its high-quality materials and meticulous engineering, this unit is capable of performing exceptionally in various industrial environments. Below are the key specifications and features of the BL190 model:

Key Features

Parallel Flow Design: The BL190’s parallel flow pattern is optimized for efficient heat transfer, allowing for improved thermal performance and reduced energy costs.

Compact and Lightweight: With a weight of only 12.5 kg, the BL190 is designed for easy installation and maintenance, making it perfect for facilities with limited space.

Corrosion-Resistant Construction: Crafted from high-grade stainless steel (SS 304 / SS 316L), the BL190 is built to withstand harsh conditions, ensuring durability and longevity.

Wide Temperature Range: Capable of handling temperatures from -190°C to 200°C, this heat exchanger is versatile enough for a range of applications, from refrigeration to heating processes.

Multiple Connection Options: The BL190 supports various connection types, including thread, solder, and flange, making it adaptable to different system requirements.

Optional Mounting Solutions: Optional mounting brackets (studs, brackets, or feet) provide flexibility during installation, accommodating a variety of setups.

Safety and Compliance: The BL190 is certified by leading international standards (UL, CE, BV, DNV, GL) and adheres to ISO 9001 and ISO 14001, ensuring reliability and safety in operation.

Efficient Packaging: Each unit is securely packaged in an individual box or polywood box, ensuring protection during transit.

Applications

The Mge Tech BL190 brazed plate heat exchanger is highly versatile and suitable for various applications, including:

HVAC Systems: Essential for heating, ventilation, and air conditioning systems, where efficient heat exchange is critical for maintaining comfort.

Refrigeration Systems: Ideal for commercial and industrial refrigeration, providing effective cooling while minimizing energy usage.

Chemical Processing: Built to withstand the demands of chemical processing, the BL190 ensures reliable and efficient thermal management in diverse applications.

Oil Cooling Systems: Perfect for hydraulic and lubrication systems, maintaining optimal temperatures to enhance machinery reliability and performance.

Advantages of Mge Tech BL190

Expertise in Engineering: Mge Tech is dedicated to delivering innovative solutions tailored to meet the unique needs of various industries. Our engineering team continually enhances product design through rigorous research and development.

Quality Assurance: Each BL190 unit undergoes strict quality control measures to ensure compliance with international standards, providing our customers with products that are safe and reliable.

Energy Efficiency: The BL190 is designed to promote energy conservation, helping clients reduce operational costs while minimizing their environmental impact.

Dedicated Customer Support: We prioritize our customers, offering personalized solutions and comprehensive support from initial inquiry to installation and beyond.

Installation and Maintenance

Installation

Installing the Mge Tech BL190 is a straightforward process. Follow these steps for successful installation:

Preparation: Ensure the installation area is clean and free of debris. Gather all necessary tools and materials.

Connection: Choose the appropriate connection type (thread, solder, or flange) based on your system requirements. Ensure all connections are secure to prevent leaks.

Mounting: Utilize the optional mounting brackets (studs, brackets, or feet) to securely install the BL190 in the desired location.

Testing: After installation, perform a thorough inspection and test the unit to ensure it operates efficiently and effectively.

Maintenance

To ensure the longevity and optimal performance of the BL190 brazed plate heat exchanger, regular maintenance is crucial. Here are some maintenance tips:

Visual Inspections: Regularly inspect the heat exchanger for any signs of wear, corrosion, or leaks. Address any issues promptly to prevent further damage.

Cleaning: Depending on the application, periodic cleaning may be necessary to remove contaminants that could impede performance. Follow manufacturer guidelines for cleaning procedures.

Performance Monitoring: Monitor the performance of the heat exchanger by checking flow rates, temperatures, and pressures to ensure it operates within specified limits.

Professional Servicing: Consider scheduling periodic professional servicing to maintain optimal performance and extend the lifespan of the unit.

Conclusion

The Mge Tech BL190 brazed plate heat exchanger represents a powerful solution for industries seeking efficient and reliable heat transfer. With its innovative design, durable construction, and versatility, the BL190 is well-suited for a wide range of applications.

Whether for HVAC, refrigeration, chemical processing, or oil cooling, the BL190 delivers the performance and reliability necessary to maintain operational excellence. For more information or to discuss your specific requirements, please contact us at info@mge-tech.com or call +86 18360805587. Choose Mge Tech for cutting-edge heat exchanger solutions that enhance your operational success.