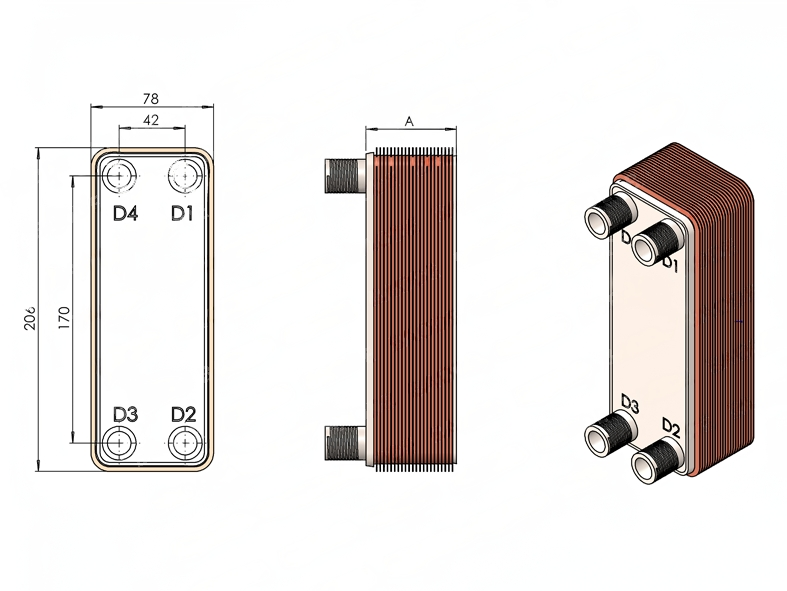

Mge Tech BL14 Brazed Plate Heat Exchanger: Compact Performance for Precision Thermal Management

| Model Details | Model | BL14 | ||

| Flow Pattern | parallel |  | ||

| Weight (kgs) | 0.6+0.08N | Approval | UL, CE, BV, DNV, GL, ISO9001, ISO14001 | |

| Max Flow (m3/h) | 3.6 | Max Pressure (bar) | 30 / 45 | |

| Plate Material | SS 304 / SS 316L | Max Temperature ℃ | 200 | |

| Conneciton Material | SS 304 | Min Temperature ℃ | -190 | |

| Brazing Material | Copper / Nickle | Packing | Individual box / Polywood box | |

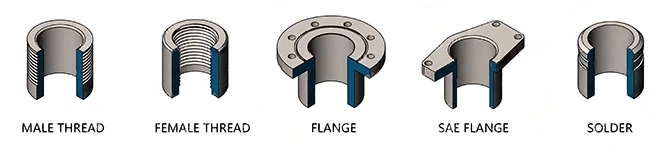

| Connection Type | Thread, Solder, Flange | Mount Bracket(Optional) | Studs, Brazcket, Feet | |

| Max Connection Size | 3/4‘’ | |||

| Freon | R22, R401, R407, R515A | |||

The Mge Tech BL14 brazed plate heat exchanger offers an efficient, lightweight, and high-performance thermal solution. Designed for compact spaces and versatile applications, the BL14 delivers excellent heat transfer while maintaining durability under a range of environmental and operating conditions. Whether you are working in HVAC systems, industrial processes, refrigeration units, or marine operations, the BL14 ensures reliable performance and easy installation with minimal maintenance requirements.

In this guide, we’ll explore the key features, technical specifications, applications, and maintenance tips to help you determine how the BL14 brazed plate heat exchanger can meet your operational needs.

Key Features of the BL14 Brazed Plate Heat Exchanger

1. Compact and Lightweight Design

Weighing only 0.6 kg + 0.08N, the BL14 is a lightweight heat exchanger ideal for compact spaces. Its small size and weight simplify installation and make it the perfect solution for applications where space constraints are a priority.

2. Parallel Flow Pattern for Efficient Heat Transfer

The parallel flow design enhances the efficiency of heat transfer by allowing multiple fluid paths to run simultaneously. This ensures a smooth, uninterrupted exchange of energy, resulting in optimized performance in various systems such as HVAC units and industrial cooling processes.

3. Durable Materials for Longevity

The BL14 is made from high-quality stainless steel (SS 304 or SS 316L), providing excellent corrosion resistance and long-term durability. The use of SS 304 for connection points ensures a strong and secure fluid transfer system, even in harsh environments.

4. Wide Temperature and Pressure Range

Operating within an impressive temperature range of -190°C to 200°C, the BL14 is suitable for both high-temperature heating and low-temperature cooling applications. Additionally, it can handle pressures of 30 bar, with an optional upgrade to 45 bar for more demanding applications.

5. Flexible Connection Options

The BL14 offers multiple connection types, including thread, solder, and flange options. This flexibility makes it easy to integrate into both existing systems and new installations, reducing the need for additional fittings or modifications.

6. Copper or Nickel Brazing for Versatile Use

Depending on the application, the BL14 can be brazed with either copper or nickel. Copper brazing is suitable for general use, while nickel brazing provides enhanced resistance to corrosive fluids and aggressive environments, such as marine or chemical applications.

7. Optional Mounting Brackets for Secure Installation

The BL14 offers optional mounting brackets, including studs, brackets, or feet, to ensure a stable and secure installation. This is particularly useful in dynamic environments with vibrations or movement.

8. Certified for Quality and Safety

With UL, CE, BV, DNV, and GL approvals, the BL14 meets international safety and quality standards. Additionally, the product is certified under ISO9001 and ISO14001, ensuring environmentally friendly manufacturing and top-quality performance.

Applications of the BL14 Brazed Plate Heat Exchanger

The BL14 is designed to meet the needs of a wide range of industries. Its compact size, high thermal efficiency, and durable design make it suitable for various applications, including:

HVAC Systems

The BL14 ensures efficient heat transfer in residential and commercial HVAC systems. Its ability to handle both heating and cooling makes it ideal for heat pumps, air conditioning units, and ventilation systems.Refrigeration Units

The BL14 is compatible with multiple refrigerants, including R22, R401, R407, and R515A, making it perfect for refrigeration systems such as cold storage facilities, chillers, and freezers.Industrial Cooling Systems

In industrial settings, precise thermal control is essential for machinery and process optimization. The BL14 provides stable heat transfer in chemical plants, power generation facilities, and manufacturing equipment.Marine and Offshore Applications

Thanks to its corrosion-resistant materials and robust construction, the BL14 is suitable for marine and offshore environments. It ensures reliable thermal exchange in shipboard cooling systems and offshore platform equipment.Food and Beverage Industry

The BL14 helps maintain precise temperatures during food processing and beverage cooling, ensuring product safety and quality. Its compact design allows for easy integration into existing production lines.

Installation Guidelines

Installing the BL14 brazed plate heat exchanger is straightforward, thanks to its lightweight design and flexible connection options. Follow these steps to ensure a smooth installation:

Prepare the Installation Site

Ensure the installation area is clean and that the connections match the required thread, solder, or flange configuration.Secure the Heat Exchanger

If mounting brackets are used, fasten the heat exchanger securely using studs, brackets, or feet to prevent movement or vibration during operation.Connect the Inlet and Outlet Pipes

Carefully attach the fluid lines to the appropriate connections. Use thread sealants or solder where necessary to ensure a leak-free connection.Pressure and Leak Testing

Perform a pressure test after installation to confirm that the system operates within the specified limits. Check for any leaks and tighten connections if necessary.System Monitoring

Monitor the system during the initial operation to verify that the BL14 is functioning correctly. Make adjustments to flow rates as needed to ensure optimal heat exchange.

Maintenance Tips for Long-Term Performance

The BL14 requires minimal maintenance, but routine care will ensure optimal performance and a longer lifespan.

Routine Inspections

Check the heat exchanger periodically for signs of wear, corrosion, or leaks. Early detection helps prevent more significant problems.Cleaning

In applications prone to scaling or debris buildup, regular cleaning of the plates will maintain efficiency. A simple flushing process can remove most deposits.Monitor Operating Conditions

Keep track of flow rates and operating temperatures to ensure the system is running efficiently. Sudden changes may indicate blockages or wear that needs attention.Seal Replacement

Inspect gaskets and seals periodically. Replace worn-out components promptly to maintain a leak-free operation.Professional Servicing

For more complex maintenance or repairs, consider hiring professional technicians to service the BL14.

Conclusion

The Mge Tech BL14 brazed plate heat exchanger is a compact, efficient, and versatile solution for various thermal management needs. Its lightweight design, parallel flow pattern, and high-grade materials make it suitable for industries ranging from HVAC and refrigeration to food processing and marine operations.

With certifications for quality and safety, the BL14 ensures reliable performance and peace of mind. Its ability to operate across a wide temperature and pressure range makes it a powerful addition to any heat exchange system. Whether you need efficient cooling, heating, or process optimization, the BL14 provides a cost-effective and durable solution.

For more information, contact info@mge-tech.com or visit our website. Choose Mge Tech for innovative heat exchanger solutions that drive efficiency and performance.