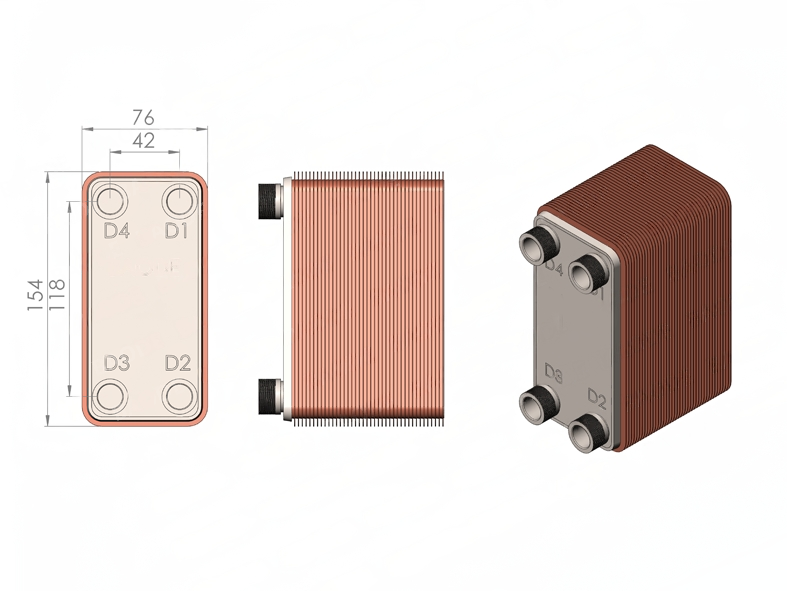

Mge Tech BL12 Brazed Plate Heat Exchanger: Compact, Efficient, and Versatile Thermal Solution

| Model Details | Model | BL12 | ||

| Flow Pattern | parallel |  | ||

| Weight (kgs) | 0.3+0.08N | Approval | UL, CE, BV, DNV, GL, ISO9001, ISO14001 | |

| Max Flow (m3/h) | 3.6 | Max Pressure (bar) | 30 / 45 | |

| Plate Material | SS 304 / SS 316L | Max Temperature ℃ | 200 | |

| Conneciton Material | SS 304 | Min Temperature ℃ | -190 | |

| Brazing Material | Copper / Nickle | Packing | Individual box / Polywood box | |

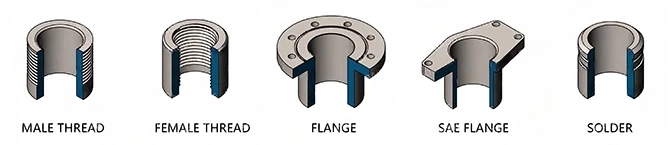

| Connection Type | Thread, Solder, Flange | Mount Bracket(Optional) | Studs, Brazcket, Feet | |

| Max Connection Size | 3/4‘’ | |||

| Freon | R22, R401, R407, R515A | |||

The Mge Tech BL12 brazed plate heat exchanger (BPHE) is a high-performance, lightweight solution designed for industries that require precise thermal control. With a focus on compact size, efficient heat transfer, and high durability, the BL12 ensures excellent performance even in challenging environments. This heat exchanger is ideal for applications such as HVAC systems, refrigeration, food processing, and marine operations.

In this guide, we’ll take a deep dive into the technical specifications, key features, potential applications, installation requirements, and maintenance tips for the BL12 model.

Key Features of the BL12 Brazed Plate Heat Exchanger

1. Ultra-Lightweight and Compact Design

Weighing just 0.3 kg + 0.08N, the BL12 is one of the most lightweight heat exchangers available, making it the ideal choice for space-restricted installations. Its compact structure ensures easy handling and installation, even in tight mechanical systems.

2. Parallel Flow Pattern for Enhanced Efficiency

The BL12 features a parallel flow design, enabling smooth and simultaneous heat transfer through multiple channels. This ensures optimal energy exchange, minimizing temperature differentials and maintaining consistent system performance.

3. High-Quality Materials for Long-Lasting Durability

Built from SS 304 or SS 316L stainless steel, the plates offer superior resistance to corrosion and wear, making the BL12 ideal for both standard and harsh environments. The copper or nickel brazing adds further durability, ensuring excellent performance over a long operational life.

- Copper brazing: Suitable for general-purpose applications.

- Nickel brazing: Provides enhanced resistance in marine or chemically aggressive environments.

4. Wide Operating Temperature and Pressure Range

The BL12 is designed to handle extreme temperature ranges from -190°C to 200°C, making it perfect for both high-temperature heating and low-temperature cooling. Additionally, the heat exchanger can operate efficiently at a pressure of 30 bar, with an optional upgrade to 45 bar for more demanding systems.

5. Multiple Connection Types for Easy Installation

Whether you need threaded, soldered, or flanged connections, the BL12 offers flexible options to suit different system setups. This flexibility ensures seamless integration into both new and existing systems.

6. Optional Mounting Brackets for Stability

For installations requiring secure mounting, the BL12 offers optional studs, brackets, or feet. These accessories provide added stability in environments subject to vibration or movement.

7. Certified for Global Safety and Quality Standards

The BL12 meets rigorous safety and quality standards with approvals from UL, CE, BV, DNV, and GL. Additionally, the ISO9001 and ISO14001 certifications reflect a commitment to sustainable manufacturing and superior product quality.

Applications of the BL12 Brazed Plate Heat Exchanger

The BL12 is a versatile solution suitable for various industries. Its lightweight design and robust performance make it an excellent choice for both commercial and industrial applications.

1. HVAC Systems

The BL12 ensures efficient heating and cooling in residential, commercial, and industrial HVAC systems. It is particularly effective in heat pumps, air conditioning units, and ventilation systems where space-saving designs are required.

2. Refrigeration and Cooling Systems

Designed to work with multiple refrigerants such as R22, R401, R407, and R515A, the BL12 plays a crucial role in chillers, cold storage units, and food preservation systems. Its ability to operate in low temperatures makes it ideal for freezers and cold chains.

3. Marine and Offshore Environments

The nickel-brazed variant of the BL12 provides superior resistance to seawater and chemical exposure, making it a valuable asset for shipboard cooling systems and offshore equipment.

4. Food and Beverage Processing

In industries like food and beverage production, maintaining precise temperature control is essential. The BL12 can be integrated into systems for process cooling and pasteurization, ensuring product quality and safety.

5. Industrial Process Control

For chemical plants, power generation units, and manufacturing facilities, the BL12 offers precise temperature regulation to optimize equipment performance and extend operational life.

Installation Guidelines for the BL12

The BL12 brazed plate heat exchanger is designed for easy and fast installation. Follow these steps to ensure a smooth setup:

Prepare the Installation Area

Ensure that the installation space is clean and ready. Verify that the inlet and outlet connections match the required configuration (thread, solder, or flange).Secure the Heat Exchanger

If using mounting brackets, fasten the BL12 securely with studs, brackets, or feet to prevent movement during operation.Connect Inlet and Outlet Pipes

Attach the fluid lines carefully to the heat exchanger’s 3/4’’ connections. Use thread sealants or solder as needed to prevent leaks.Test the System for Leaks

After installation, perform a pressure and leak test to ensure the system is operating properly. Tighten any loose connections if necessary.Monitor Performance During Initial Operation

Observe the heat exchanger during the first few hours of operation. Check for optimal flow rates and ensure the system reaches the desired temperatures.

Maintenance Tips for Long-Term Efficiency

The BL12 brazed plate heat exchanger requires minimal maintenance, but regular inspections will ensure it continues to perform at its best.

Periodic Inspections

Inspect the unit regularly for signs of wear, leaks, or corrosion. Address any issues promptly to prevent system downtime.Cleaning and Descaling

In applications with hard water or heavy scaling, flush the heat exchanger periodically to remove buildup. This helps maintain optimal heat transfer efficiency.Monitor System Conditions

Keep track of flow rates and operating temperatures. Unusual changes may indicate blockages or performance issues that need to be addressed.Seal and Gasket Replacement

Inspect gaskets and seals for wear and replace them as needed to maintain a leak-free system.Professional Maintenance

For complex repairs or maintenance, engage qualified technicians to ensure the heat exchanger continues to meet performance standards.

Conclusion

The Mge Tech BL12 brazed plate heat exchanger offers a perfect combination of lightweight design, high efficiency, and durability. With its wide range of applications, from HVAC and refrigeration to marine and industrial process control, the BL12 delivers reliable performance even in extreme conditions.

Its flexible connection options, optional mounting brackets, and robust materials make it easy to install and maintain. Certified by leading safety and quality organizations, the BL12 is an excellent choice for industries that demand precision and reliability.

For more information about the BL12 model or to request a quote, contact info@mge-tech.com. Discover how the Mge Tech BL12 brazed plate heat exchanger can enhance your operations with superior thermal management and efficiency.