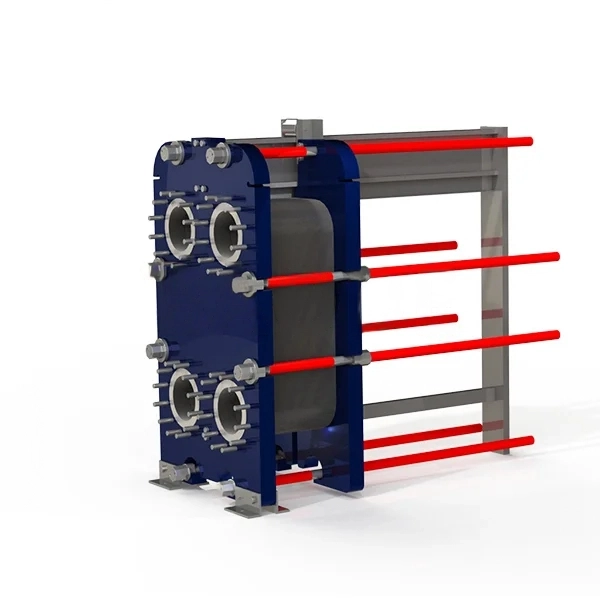

SB200 Gasket Plate Heat Exchanger: A Robust Solution for High-Volume Applications

| Model Details | Model | SB200 | ||

| Flow Patten | Parallel | Channel Angel | D 120° / X 60° | |

| Channel Depth | 4 mm | Approval | UL, CE, BV, DNV, GL, | |

| Max Flowrate Kg/s | 190 | ISO9001, ISO14001 | ||

| Plate Material | SS / TI / SMO / Hastelloy | Frame Mateial | Carbon steel with pait | |

| Plate Thickness mm | 0.5/ 0.6 / 0.7 | Max Pressure (bar) | 10/16 | |

| Gasket Material | NBR/ EPDM / VITON | Max Temp (C°) | 110/140/180 (depends on gasket material) | |

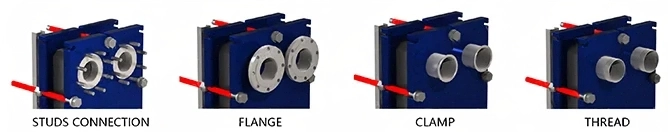

| Connction Type | Flange, Thread, Clamp, Studs | Min Temp (C°) | 0 | |

| Connction Size | DN200 | Packing | Polywood box |

In industrial processes, efficient heat transfer is paramount for optimal performance and energy conservation. The SB200 gasket plate heat exchanger from Mge Tech offers an advanced solution designed to meet the demands of high-volume applications across various sectors. With its robust construction, customizable features, and exceptional efficiency, the SB200 stands out as a reliable choice for heat exchange requirements. This article provides an in-depth look at the features, specifications, and benefits of the SB200 model.

Overview of the SB200 Model

The SB200 gasket plate heat exchanger is engineered to deliver high thermal efficiency in a compact design. It utilizes a parallel flow pattern, which enhances the heat transfer process by allowing the two fluids to flow in the same direction. This innovative design, combined with high-quality materials, ensures that the SB200 can handle demanding applications with ease and reliability.

Design and Construction

Flow Pattern and Channel Design

The SB200 features a parallel flow pattern, which optimizes heat transfer efficiency. This design allows for greater temperature differentials between the two fluids, resulting in improved thermal performance. The channel angles of D 120° and X 60° are specifically engineered to facilitate smooth fluid flow, minimizing turbulence and pressure drops.

Materials of Construction

Mge Tech provides a range of material options for the SB200, allowing users to tailor the heat exchanger to their specific operational needs:

Plate Materials: Users can choose from various plate materials such as Stainless Steel, Titanium, SMO, and Hastelloy. Each material is selected based on the compatibility with the fluids being processed and the operational environment. For instance, Hastelloy is ideal for corrosive substances, while Titanium is suitable for lightweight and high-strength applications.

Frame Material: The frame of the SB200 is constructed from durable carbon steel, finished with protective paint to enhance resistance against environmental factors, thus ensuring longevity and reliability.

Gasket Materials: The choice of gaskets includes NBR, EPDM, and VITON, enabling users to select the appropriate material based on temperature and chemical compatibility requirements. This flexibility ensures optimal performance across a range of applications.

Pressure and Temperature Ratings

Designed for high-pressure applications, the SB200 can withstand a maximum pressure of 16 bar. Its temperature capabilities range from 0°C to 180°C, depending on the selected gasket material. This wide operational range makes the SB200 suitable for various industrial applications.

Approvals and Certifications

The SB200 model is compliant with numerous international standards, ensuring it meets stringent safety and performance criteria. The following certifications demonstrate the reliability and quality of the SB200:

- Approvals: UL, CE, BV, DNV, GL

- Quality Management: ISO9001, ISO14001

These certifications give customers confidence in the SB200’s safety, efficiency, and performance.

Advantages of the SB200 Gasket Plate Heat Exchanger

High Thermal Efficiency: The parallel flow design of the SB200 allows for exceptional heat transfer, resulting in reduced energy consumption and lower operating costs.

Robust Construction: Built to withstand demanding environments, the SB200 features high-quality materials and a sturdy design, ensuring long-term reliability.

Versatile Applications: The SB200 is suitable for a wide array of applications, including food processing, pharmaceuticals, HVAC systems, and chemical manufacturing, making it a versatile choice for various industries.

Easy Maintenance: The gasket plate design enables straightforward disassembly for cleaning and maintenance, allowing for minimal downtime.

Customizable Features: With various material and gasket options, the SB200 can be tailored to meet specific operational requirements, ensuring optimal performance in diverse applications.

Applications of the SB200 Heat Exchanger

The SB200 gasket plate heat exchanger can be employed in various industries, providing efficient heat transfer solutions:

1. Food and Beverage Industry

In the food and beverage sector, maintaining product quality while ensuring compliance with health and safety standards is crucial. The SB200 is well-suited for applications such as pasteurization, heating, and cooling, thanks to its sanitary design and high thermal efficiency.

2. Pharmaceutical Manufacturing

Pharmaceutical processes require precise temperature control and high levels of cleanliness. The SB200’s ability to handle high pressures and temperatures makes it an ideal choice for heating and cooling applications in pharmaceutical production, ensuring product integrity and safety.

3. HVAC Systems

The SB200 is instrumental in heating, ventilation, and air conditioning (HVAC) systems, offering efficient heat exchange for both heating and cooling applications. Its compact size and high efficiency make it suitable for residential and commercial installations.

4. Chemical Processing

In chemical manufacturing, the SB200 can be utilized for heat recovery, cooling, and process heating. Its robust construction and versatility in material selection allow it to handle aggressive fluids safely and effectively.

5. Renewable Energy Applications

As industries shift towards sustainable practices, the SB200 gasket plate heat exchanger is increasingly used in renewable energy systems, such as geothermal heating and cooling. Its efficiency contributes to energy savings and supports environmental goals.

Installation and Operation

Installation Guidelines

Proper installation of the SB200 gasket plate heat exchanger is crucial for optimal performance and longevity. Here are some key considerations:

Connection Type: The SB200 supports various connection types, including flange, thread, clamp, and studs. Selecting the appropriate connection based on the installation requirements is essential.

Orientation: The orientation of the heat exchanger can impact performance. It is recommended to install the SB200 in a position that allows for easy access for maintenance and cleaning.

Fluid Flow: Ensuring the correct flow pattern and maintaining the required flow rates will maximize the heat exchanger’s efficiency and effectiveness.

Operating Procedures

To maintain optimal performance, the SB200 requires regular monitoring and maintenance:

Temperature and Pressure Monitoring: Regularly check the operating temperature and pressure to ensure they remain within the specified limits for safe operation.

Maintenance: Periodic disassembly for cleaning is necessary, especially in applications involving food or pharmaceuticals, to uphold hygiene and performance.

Gasket Inspection: Regularly inspect gaskets for wear and damage. Replacing gaskets as needed will prevent leaks and maintain the integrity of the heat exchanger.

Conclusion

Mge Tech’s SB200 gasket plate heat exchanger is a robust solution designed for high-volume applications across various industries. With its advanced design, high-quality materials, and versatile capabilities, the SB200 model offers unparalleled thermal efficiency and reliability. Whether in food processing, pharmaceuticals, HVAC, or chemical manufacturing, the SB200 provides an efficient and dependable solution for your heat transfer needs.

Investing in the SB200 means choosing a heat exchanger that promises efficiency, durability, and superior performance, supporting your operations while contributing to energy savings and sustainability. For more information about the SB200 gasket plate heat exchanger and how it can benefit your business, contact Mge Tech today.