Comprehensive Overview of the B300B Gasket Plate Heat Exchanger

| Model Details | Model | B300B | ||

| Flow Patten | Parallel | Channel Angel | D 120° / X 60° | |

| Channel Depth | 3.4 mm | Approval | UL, CE, BV, DNV, GL, | |

| Max Flowrate Kg/s | 250 | ISO9001, ISO14001 | ||

| Plate Material | SS / TI / SMO / Hastelloy | Frame Mateial | Carbon steel with pait | |

| Plate Thickness mm | 0.5/ 0.6 / 0.7 | Max Pressure (bar) | 10/16 | |

| Gasket Material | NBR/ EPDM / VITON | Max Temp (C°) | 110/140/180 (depends on gasket material) | |

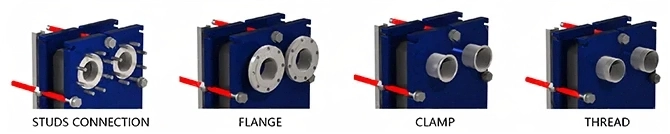

| Connction Type | Flange, Thread, Clamp, Studs | Min Temp (C°) | 0 | |

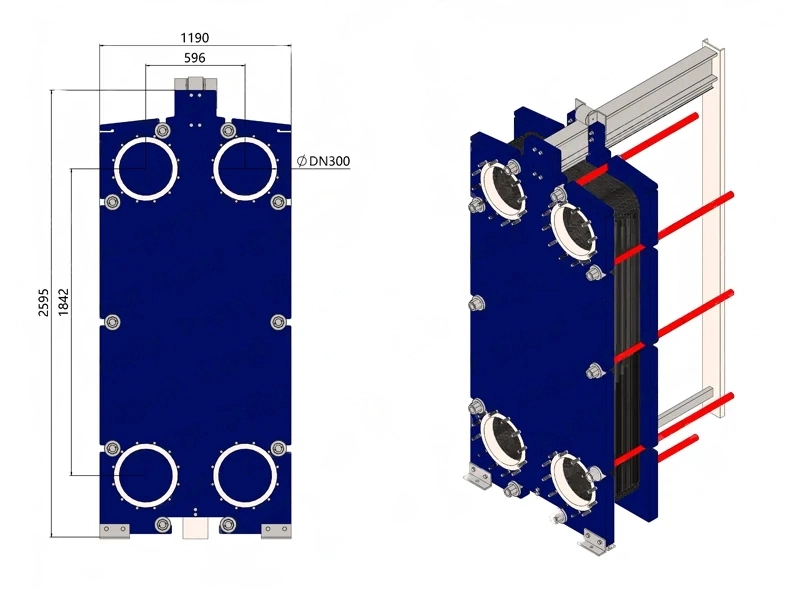

| Connction Size | DN300 | Packing | Polywood box |

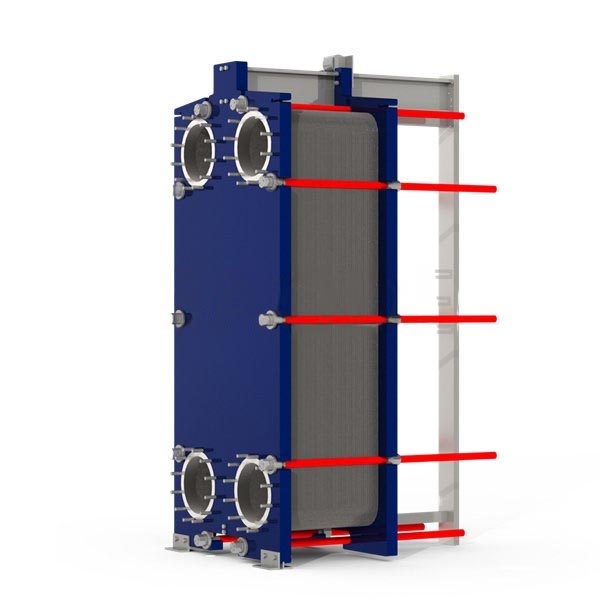

The B300B gasket plate heat exchanger is a cutting-edge solution designed for efficient thermal management across various industries. With its innovative design and robust construction, the B300B ensures optimal heat transfer while maintaining durability and reliability. This article provides an in-depth look at the specifications, design features, advantages, applications, and maintenance of the B300B heat exchanger.

Design Features

Flow Pattern and Channel Design

The parallel flow pattern of the B300B enhances the efficiency of heat exchange processes. This design minimizes flow resistance, promoting effective fluid movement and maximizing thermal performance. The D 120° / X 60° channel angle is specifically engineered to ensure smooth fluid dynamics, while the 3.4 mm channel depth increases the surface area available for heat transfer, contributing to superior heat exchange efficiency.

Material Selection

The material composition of the B300B is pivotal to its performance:

Plate Materials: The options of Stainless Steel, Titanium, SMO, and Hastelloy allow for flexibility in accommodating various fluid types and environmental conditions. Stainless Steel is renowned for its corrosion resistance, while Titanium and Hastelloy offer enhanced durability in aggressive environments, ensuring long-lasting operation.

Frame Material: The carbon steel frame with paint provides structural integrity and protects against external environmental factors, further enhancing the heat exchanger’s lifespan.

Gasket Materials: The variety of gasket materials—NBR, EPDM, and VITON—allows customization based on specific operational needs, ensuring leak prevention and supporting stable temperature control.

Performance Ratings

The B300B is designed to meet rigorous industrial standards, making it a reliable choice for various applications:

Maximum Pressure: With ratings up to 16 bar, this model can withstand high-pressure conditions, making it suitable for demanding environments.

Temperature Range: Operating effectively within a range of 0°C to 180°C (depending on the gasket material) allows the B300B to provide efficient heating and cooling solutions.

Certifications and Compliance

The B300B gasket plate heat exchanger is manufactured under stringent quality standards, ensuring safety and reliability:

- Approvals: The unit has received certifications from UL, CE, BV, DNV, and GL, reflecting its compliance with international safety and performance standards.

- Quality Management: Adherence to ISO9001 and ISO14001 certifications guarantees that the B300B is produced with consistent quality and environmental responsibility.

Advantages of the B300B Gasket Plate Heat Exchanger

High Efficiency: The design of the B300B ensures efficient heat transfer, leading to reduced energy consumption and lower operating costs.

Durable Construction: Built from high-quality materials, the B300B is designed to withstand challenging operating conditions, offering reliability and longevity.

Versatile Applications: The heat exchanger’s adaptability makes it suitable for a wide range of industries, including food processing, pharmaceuticals, chemical manufacturing, and HVAC systems.

Easy Maintenance: The gasket plate design simplifies maintenance and cleaning processes, minimizing downtime and ensuring continuous operation.

Compact Size: The B300B’s compact footprint allows for installation in space-limited environments without sacrificing heat transfer efficiency.

Applications of the B300B Heat Exchanger

The versatility of the B300B makes it applicable in various industries, providing efficient heat exchange solutions:

1. Food and Beverage Industry

The B300B is ideal for processes such as pasteurization, heating, and cooling in food production. Its hygienic design ensures compliance with safety standards while maintaining product quality.

2. Pharmaceutical Manufacturing

In pharmaceutical applications, maintaining precise temperature control is essential. The B300B offers reliable heating and cooling solutions while adhering to strict cleanliness requirements.

3. Chemical Processing

The B300B excels in heat recovery, cooling, and process heating in chemical manufacturing. Its robust design and material options allow it to handle aggressive fluids safely.

4. HVAC Systems

In heating, ventilation, and air conditioning (HVAC) systems, the B300B provides efficient heat exchange, contributing to energy savings and improved indoor climate control.

5. Renewable Energy Applications

The B300B is increasingly utilized in renewable energy systems, such as geothermal heating and cooling. Its efficiency supports sustainability goals while maximizing energy savings.

Installation and Operation

Installation Guidelines

For optimal performance, proper installation of the B300B gasket plate heat exchanger is crucial:

Connection Type: Choose from various connection types (flange, thread, clamp, or studs) based on the installation requirements to ensure secure attachment.

Orientation: Install the heat exchanger to allow easy access for maintenance and cleaning, facilitating routine checks for optimal operation.

Fluid Flow: Maintain the correct flow pattern and ensure that flow rates remain within specified limits to optimize heat exchange efficiency.

Operating Procedures

To ensure the continued efficiency and longevity of the B300B, regular monitoring and maintenance are necessary:

Temperature and Pressure Monitoring: Regularly check operating temperatures and pressures to ensure they remain within recommended limits for safe operation.

Routine Maintenance: Periodically disassemble the heat exchanger for cleaning, especially in sanitary applications, to maintain hygiene and performance.

Gasket Inspection: Regularly inspect gaskets for wear and damage. Replacing gaskets as needed will prevent leaks and maintain the integrity of the heat exchanger.

Conclusion

The B300B gasket plate heat exchanger from Mge Tech stands as a premier solution for efficient heat transfer across various industrial applications. With its advanced design, high-quality materials, and exceptional performance capabilities, the B300B model is a reliable choice for industries including food and beverage, pharmaceuticals, HVAC, chemical processing, and renewable energy.

Investing in the B300B means opting for a heat exchanger that guarantees efficiency, durability, and superior performance, ultimately supporting your operations while contributing to energy savings and sustainability. For further information on the B300B gasket plate heat exchanger and its potential benefits for your business, contact Mge Tech today.