In the world of thermal management and heat transfer technologies, brazed plate heat exchangers (BPHEs) have emerged as a leading solution for various industrial applications. Mge Tech is at the forefront of this innovation, providing a range of high-performance brazed plate heat exchangers designed for superior efficiency, durability, and compactness. This article explores the features, benefits, and applications of Mge Tech’s brazed plate heat exchangers, including various models such as BL12, BL14, BL20, and more.

Understanding Brazed Plate Heat Exchangers

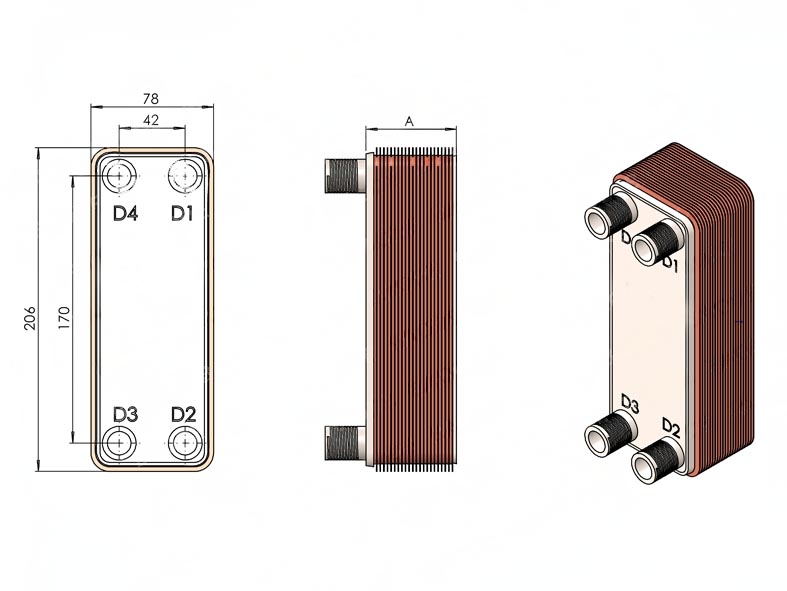

Brazed plate heat exchangers are composed of numerous thin plates stacked together, creating channels for fluids to flow through. The plates are made of stainless steel and are bonded together through a brazing process, which involves heating the assembly in a controlled atmosphere to allow the filler metal to flow and create a strong, leak-proof seal. This design offers several advantages over traditional heat exchangers:

- Compact Size: The design allows for a significant reduction in space requirements, making them ideal for applications with limited space.

- High Efficiency: The large surface area and turbulent flow of fluids within the channels promote superior heat transfer efficiency.

- Durability: The robust construction ensures longevity and the ability to withstand high pressures and temperatures.

- Corrosion Resistance: Made from high-quality materials, these heat exchangers resist corrosion, ensuring reliability in demanding environments.

Key Features of Mge Tech’s Brazed Plate Heat Exchangers

Mge Tech’s brazed plate heat exchangers are engineered with various industrial applications in mind. Some notable features include:

- Robust Construction: Our heat exchangers are designed to withstand high pressures and temperatures, ensuring reliable performance over extended periods.

- High Corrosion Resistance: The use of stainless steel materials provides excellent resistance to corrosion, making them suitable for a wide range of fluids, including aggressive media.

- Minimal Maintenance: The simple design minimizes the need for maintenance, allowing for uninterrupted operations and reduced downtime.

- Customizable Solutions: Mge Tech offers a variety of models and configurations to meet specific application requirements, ensuring optimal performance.

Applications of Brazed Plate Heat Exchangers

Mge Tech’s brazed plate heat exchangers are versatile and can be used in a multitude of industrial applications, including:

- HVAC Systems: For heating, ventilation, and air conditioning applications, where efficient heat exchange is crucial for maintaining desired temperatures.

- Refrigeration Systems: Used in chillers and refrigeration units to facilitate effective cooling and energy conservation.

- Chemical Processing: Ideal for transferring heat in chemical processes, where durability and corrosion resistance are paramount.

- Food and Beverage Industry: Used for pasteurization and cooling processes, ensuring food safety and quality.

- Oil Cooling Systems: Essential for maintaining optimal temperatures in lubrication systems and hydraulic applications.

Mge Tech’s Product Range

Mge Tech offers a comprehensive range of brazed plate heat exchangers, each designed to meet specific operational needs. Below are the details of our prominent models:

BL12

The BL12 model is compact yet efficient, making it ideal for smaller systems where space is at a premium. It is perfect for HVAC applications and provides excellent heat transfer performance.

BL14

The BL14 model offers increased capacity while maintaining a compact footprint. It is well-suited for industrial applications that require robust performance in a limited space.

BL20

With a slightly larger design, the BL20 model can handle higher flow rates, making it ideal for refrigeration and cooling applications.

BL21

The BL21 model is designed for more demanding applications, offering enhanced thermal efficiency and durability. It is suitable for both heating and cooling processes.

BL26

The BL26 model provides versatility and high performance, making it suitable for various industries, including food processing and chemical applications.

BL30

A reliable choice for oil cooling applications, the BL30 model ensures optimal heat transfer and minimal maintenance, enhancing operational efficiency.

BL50

The BL50 model is engineered for larger industrial applications, providing exceptional heat transfer capacity and durability, even in harsh environments.

BL60

Designed for high-performance requirements, the BL60 model excels in cooling and heating applications across diverse industries.

BL95

The BL95 model combines compact design with high efficiency, making it an excellent choice for specialized applications requiring precise temperature control.

BL100

The BL100 model is built for heavy-duty applications, delivering reliable performance in high-pressure and high-temperature environments.

BL120

This model is suitable for large-scale industrial applications, providing robust heat transfer capabilities while maintaining a compact design.

BL190

The BL190 model offers maximum performance for demanding applications, ensuring efficient heat transfer and reliability in various settings.

BL200

Designed for extensive industrial systems, the BL200 model provides exceptional thermal efficiency and durability, suitable for high-capacity needs.

BL210

The BL210 model is engineered for superior performance in extreme conditions, making it ideal for chemical processing and heavy-duty applications.

BL600

As one of the largest models, the BL600 is perfect for large-scale industrial operations, providing maximum heat transfer efficiency and durability.

Advantages of Choosing Mge Tech

When you choose Mge Tech’s brazed plate heat exchangers, you benefit from:

- Expertise: With years of experience in the industry, Mge Tech understands the unique needs of various applications and delivers solutions accordingly.

- Quality Assurance: Our heat exchangers undergo rigorous testing and quality checks to ensure they meet international standards and exceed customer expectations.

- Customer-Centric Approach: We prioritize our clients’ needs, providing customized solutions and comprehensive support throughout the purchasing process and beyond.

- Energy Efficiency: Our products are designed to maximize energy efficiency, helping clients reduce operational costs and minimize their environmental impact.

Conclusion

Mge Tech’s brazed plate heat exchangers represent the pinnacle of heat transfer technology, offering superior performance, durability, and efficiency. With a wide range of models tailored to meet the specific needs of various industries, Mge Tech is committed to providing reliable solutions that enhance operational performance. Whether you are in HVAC, refrigeration, chemical processing, or any other industry, our brazed plate heat exchangers are designed to deliver exceptional results.

For more information about our products or to discuss your specific needs, please contact us at info@mge-tech.com or call +86 18360805587. Choose Mge Tech for innovative heat exchanger solutions that drive your success.